How to Use AI in Predictive Maintenance?

Updated 21 Jul 2024 by Nex AI Team

Gen AI: Enhancing predictive maintenance processes.

Nex AI's talks with maintenance engineers and operations managers in manufacturing firms have uncovered several core use cases for adopting Gen AI in predictive maintenance.

We have identified two main areas where AI can significantly assist predictive maintenance processes:

- Machinery breakdown prediction

- Optimized maintenance scheduling

This is what these problems could look like in your manufacturing firm.

Use Cases: Problems AI solves in predictive maintenance.

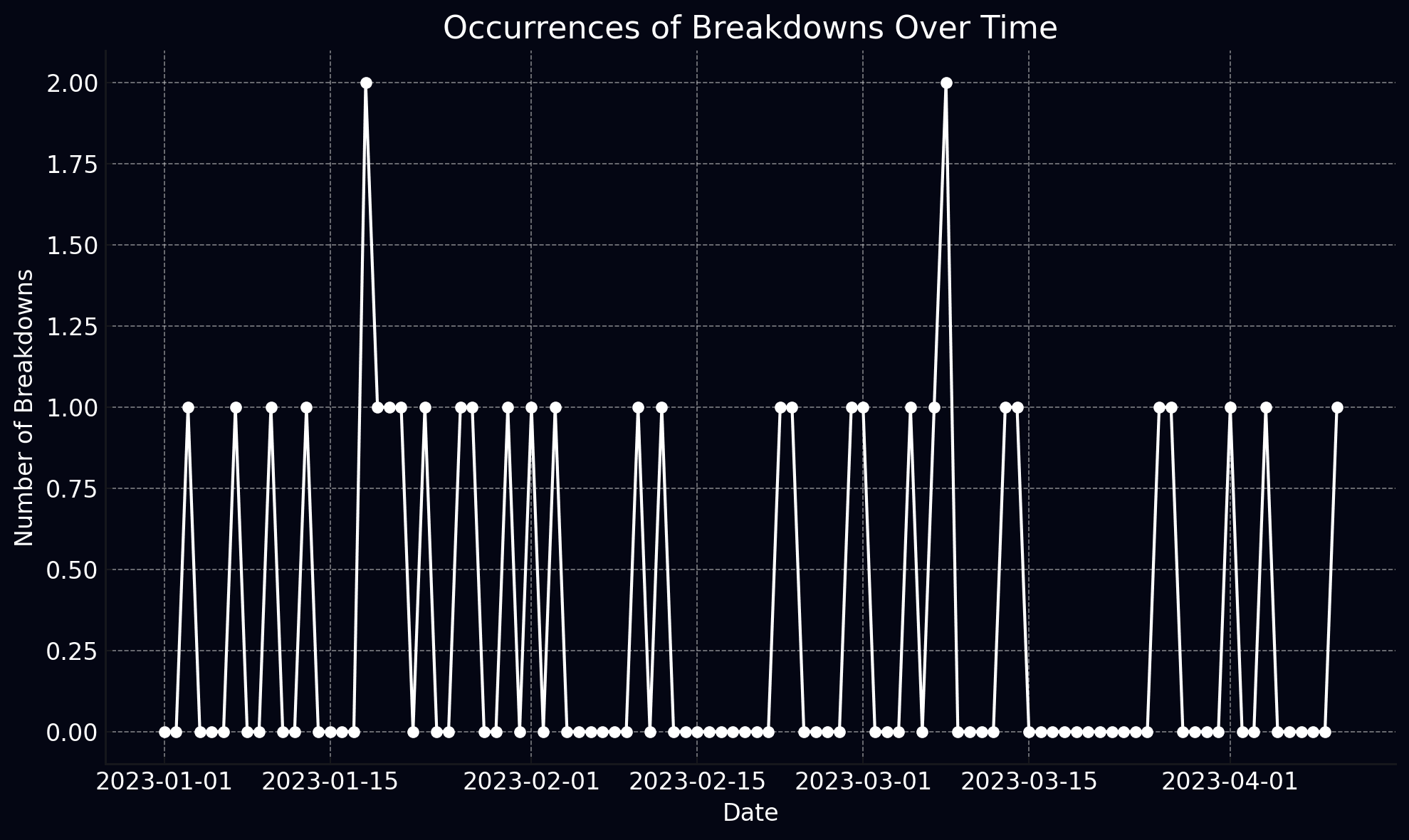

Predicting machinery breakdowns

Unexpected machinery breakdowns can lead to production delays and increased maintenance costs. Maintenance teams need accurate predictions to prevent breakdowns.

Gen AI solutions can analyze sensor data, maintenance logs, and operational parameters to predict potential machinery failures, helping teams to take proactive measures.

Optimizing maintenance schedules

Efficient maintenance scheduling is crucial to minimize downtime and operational costs. Maintenance teams need data-driven insights to optimize schedules.

Generative AI solutions can analyze historical maintenance data and operational parameters to suggest optimal maintenance schedules, reducing downtime and costs.

Identifying factors contributing to breakdowns

Understanding the factors that contribute to machinery breakdowns is essential for preventive maintenance. Maintenance teams need comprehensive data analysis.

Gen AI solutions such as Nex AI can mine sensor data, maintenance logs, and operational parameters to identify factors contributing to breakdowns, helping teams to address root causes.

Ready to enhance predictive maintenance with AI?

Contact us to try Nex for your manufacturing firm.

We'd love to learn how our solutions can help you and your teams improve predictive maintenance processes and achieve higher operational efficiency.